Internal Combustion Lift Truck Pre-Operation Inspection Checklist

ADVERTISEMENT

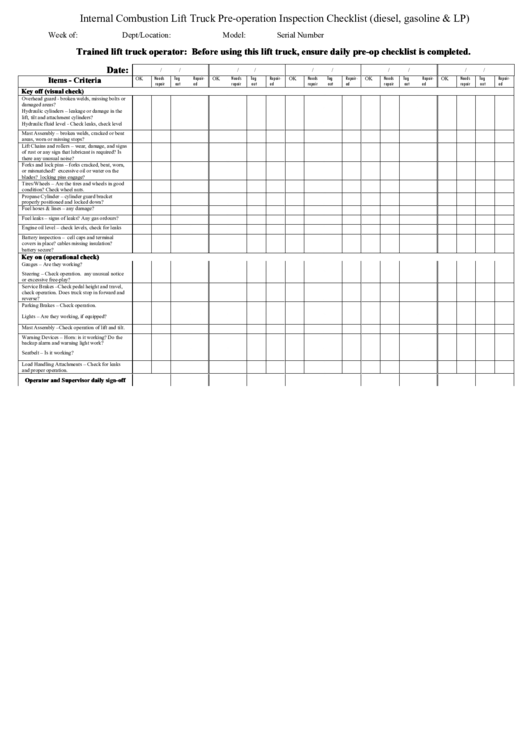

Internal Combustion Lift Truck Pre-operation Inspection Checklist (diesel, gasoline & LP)

Week of:

Dept/Location:

Model:

Serial Number

Trained lift truck operator: Before using this lift truck, ensure daily pre-op checklist is completed.

Date:

/

/

/

/

/

/

/

/

/

/

Needs

Tag

Repair-

Needs

Tag

Repair-

Needs

Tag

Repair-

Needs

Tag

Repair-

Needs

Tag

Repair-

OK

OK

OK

OK

OK

Items - Criteria

repair

out

ed

repair

out

ed

repair

out

ed

repair

out

ed

repair

out

ed

Key off (visual check)

Overhead guard - broken welds, missing bolts or

damaged areas?

Hydraulic cylinders – leakage or damage in the

lift, tilt and attachment cylinders?

Hydraulic fluid level - Check leaks, check level

Mast Assembly – broken welds, cracked or bent

areas, worn or missing stops?

Lift Chains and rollers – wear, damage, and signs

of rust or any sign that lubricant is required? Is

there any unusual noise?

Forks and lock pins – forks cracked, bent, worn,

or mismatched? excessive oil or water on the

blades? locking pins engage?

Tires/Wheels – Are the tires and wheels in good

condition? Check wheel nuts.

Propane Cylinder – cylinder guard bracket

properly positioned and locked down?

Fuel hoses & lines – any damage?

Fuel leaks – signs of leaks? Any gas ordours?

Engine oil level – check levels, check for leaks

Battery inspection – cell caps and terminal

covers in place? cables missing insulation?

battery secure?

Key on (operational check)

Gauges – Are they working?

Steering – Check operation. any unusual notice

or excessive free-play?

Service Brakes –Check pedal height and travel,

check operation. Does truck stop in forward and

reverse?

Parking Brakes – Check operation.

Lights – Are they working, if equipped?

Mast Assembly –Check operation of lift and tilt.

Warning Devices – Horn: is it working? Do the

backup alarm and warning light work?

Seatbelt – Is it working?

Load Handling Attachments – Check for leaks

and proper operation.

Operator and Supervisor daily sign-off

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1